Every year, thousands of consumer products fail before reaching store shelves. The reason? Poor design choices that ignore what users actually need. Good consumer product design bridges the gap between a brilliant idea and a product people love to use.

This guide walks you through the complete consumer product design process. You will learn how to conduct consumer research, develop concepts, engineer prototypes, and prepare products for manufacturing. Whether you are launching your first product or refining an existing design, these proven strategies will help you create products that resonate with your target audience.

Creating consumer products requires a systematic approach. This framework breaks down the design process into a repeatable system that companies and design studios use to reduce risk, improve product-market fit, and accelerate time to market. Each stage builds on the previous one, creating a clear path from concept design to finished product.

Research forms the foundation of every successful product. You need both qualitative insights and quantitative data to understand the user needs driving your design decisions.

Start with user interviews to uncover pain points your target audience faces daily. Contextual inquiry takes this further by observing people in their natural environment as they interact with existing products. Field observation reveals behaviors users might not articulate in interviews.

Your research toolkit should include:

Competitive benchmarking helps you understand what consumer product design companies already offer. Study both direct competitors and adjacent solutions. Look for gaps where consumer needs remain unmet.

Market research validates demand before you invest heavily in development. Use surveys, landing pages, or crowdfunding campaigns to gauge interest. This early validation can save months of wasted effort on products nobody wants.

The goal is transforming raw data into actionable insights. Document patterns across multiple users rather than focusing on outliers. These patterns become design constraints that guide your concept development.

Raw research data means nothing until you synthesize it into a clear problem statement. This step transforms observations into a focused design challenge that your team can rally around.

A strong problem statement identifies who experiences the problem, what they struggle with, and why current solutions fall short. For example: “Busy parents struggle to prepare healthy meals because existing meal prep tools require too much time and create excessive cleanup.”

Map your findings using an opportunity framework. Start with the insight from your research, identify the core problem it reveals, then define the specific opportunity for your consumer product design firm to address. Small examples make abstract problems concrete. “Users waste 15 minutes daily searching for misplaced items” hits harder than “storage is inconvenient.”

The best product opportunities sit at the intersection of user pain, market timing, and technical feasibility. Validate your problem definition with stakeholders before moving forward. A problem worth solving generates immediate recognition and enthusiasm from potential users.

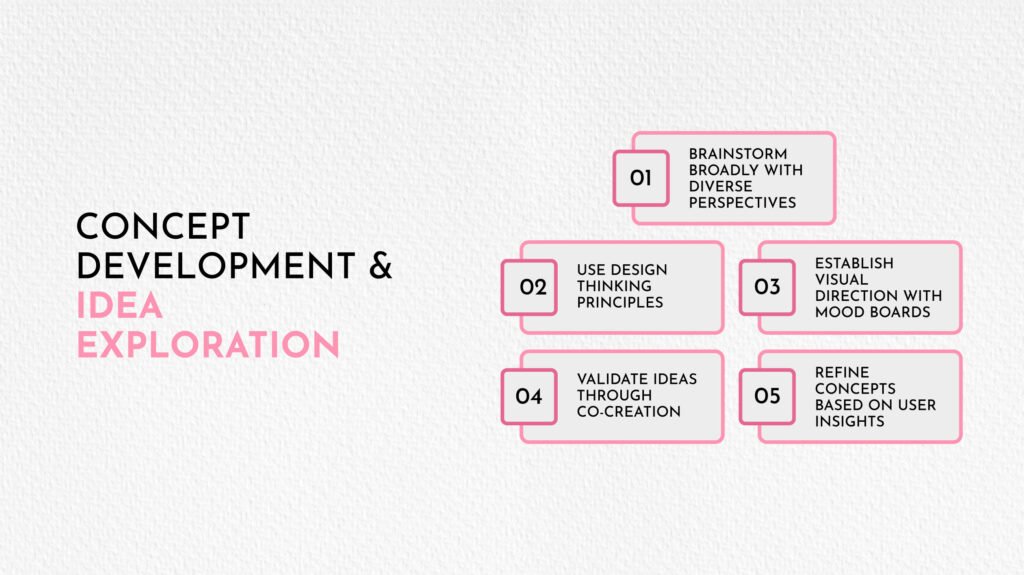

Once you define the problem, it is time to explore solutions. Concept development transforms insights into tangible product ideas through creative exploration and structured ideation.

Brainstorming sessions work best with diverse perspectives. Set a timer for rapid ideation where quantity matters more than quality. Sketching makes abstract concepts visible quickly. You do not need artistic talent to communicate product ideas through simple drawings.

Mood boards establish visual direction early. Collect images, colors, textures, and existing products that capture the aesthetic you are targeting. These boards align your design team on style before you create a single prototype.

Design thinking principles guide this exploration:

Co-creation sessions invite potential users into the design process. Show early concepts and gather immediate reactions. This collaboration often reveals needs you missed during research.

One practical example: A team designing a portable coffee maker started with twenty rough concepts. Through user feedback, they discovered people valued quiet operation over speed. This insight shaped their entire engineering approach.

Industrial design is where function meets beauty. This stage focuses on how your product feels in the hand, looks on the shelf, and fits into daily life through thoughtful form development.

Ergonomics ensures comfort during actual use. Study how people will hold, carry, and interact with your product. Test different grip sizes and angles with physical mockups. Tactile feel influences perception of quality through material texture, button resistance, and weight distribution.

Human-product interaction encompasses every touchpoint. Where do fingers naturally rest? What feedback do users need when they press a button? Can someone use your product in dim lighting? These questions reveal opportunities to improve usability.

Aesthetic coherence ties all visual elements together. Your color palette, material choices, and form language should feel intentional. Consumer psychology plays a subtle but powerful role. Rounded edges feel friendlier than sharp corners. Matte finishes suggest sophistication while glossy surfaces imply modernity.

Real-world testing reveals ergonomic flaws. Have users interact with foam models or 3D printed prototypes. Watch for awkward movements or confused expressions. The goal is creating products design that disappears into daily routines.

Great design means nothing if you cannot build it. Product engineering transforms creative concepts into manufacturable products while balancing aesthetic vision with technical reality.

Material selection affects everything from product performance to final retail price. Plastics offer design flexibility and lower costs but may limit durability. Metals provide strength and premium feel but increase weight and expense. Your choice impacts assembly cost, repair difficulty, and long-term reliability.

Electronics integration adds complexity for smart consumer electronics. You need space for circuit boards, battery access, and thermal management to prevent overheating. Early collaboration between industrial designers and electrical engineers prevents expensive redesigns later.

Durability testing reveals how products perform under stress. Drop tests, temperature cycling, and repeated use simulations expose weak points before manufacturing begins. Design for Manufacturing (DFM) principles guide feasibility decisions. Can your product be molded in a single piece? Are tolerances realistic for mass production?

Engineering constraints that shape design include:

Constraint Type | Impact on Design | Mitigation Strategy |

Material limits | Restricts forms and features | Early material testing |

Cost targets | Reduces complexity | Design-to-value analysis |

Manufacturing capability | Simplifies geometry | Factory capability review |

Sustainable design practices reduce environmental impact while potentially lowering material costs. Technical feasibility requires honest assessment. The best consumer product design companies balance innovation with practical constraints.

Computer-Aided Design (CAD) transforms sketches into precise 3D models. This digital representation becomes the blueprint for prototyping and manufacturing through modern product design software.

CAD modeling creates a virtual version of your product with exact dimensions. You can test fit, analyze stress points, and visualize assembly before building anything physical. Software like Fusion 360 or SolidWorks allows rapid iteration without wasting materials.

Prototyping methods vary by stage and budget:

3D printing has revolutionized consumer product prototyping. You can hold a physical version of your design within hours. Each prototype serves a different purpose. Early versions test basic concepts while later iterations validate technical specifications.

Iteration cycles improve designs systematically. Test a prototype, identify issues, update the CAD model, print a new version. Consumer product development companies often go through ten or more prototype iterations before finalizing designs.

The prototype represents your product idea made tangible. It transforms abstract concepts into something people can touch, use, and critique. This physical validation is essential before committing to expensive manufacturing tooling.

Building a prototype is only half the battle. Testing validates whether your design actually solves the problem you identified during research. User feedback at this stage prevents expensive mistakes after launch.

Usability testing observes real people using your prototype. Set up task-based scenarios that mirror actual use cases. Do not guide participants or explain how things work. Watch where they struggle, what they skip, and what delights them.

A/B testing compares design variations when you face tough choices. Create two versions with different button placements or color schemes. Let users interact with both and gather preference data. Behavioral analysis goes deeper than surveys through body language and facial expressions.

Effective validation includes multiple test types:

Real example: A kitchen gadget company discovered through testing that users ignored an innovative cleaning feature because it was not obvious. They redesigned the interface based on this feedback. Post-launch sales exceeded projections because the product that actually shipped matched what users wanted.

Document every change driven by user feedback. This creates a clear trail from insight to implementation. Future projects benefit from patterns you identify across multiple rounds of validation.

Your design is tested and validated. Now it is time to prepare for mass production. This handoff phase determines whether your product can be manufactured reliably at scale.

Design for Manufacturing (DFM) review catches production issues before they become expensive problems. Engineers analyze every part for manufacturability. Design for Assembly (DFA) principles minimize production time and cost. Fewer parts mean simpler assembly and lower failure rates.

Tooling design translates your CAD models into molds, dies, and fixtures. This is where your digital design becomes physical reality. Tooling represents a major investment, so getting it right matters.

Manufacturing documentation includes:

Factory communication requires clarity and patience. Detailed documentation reduces confusion. Regular video calls with visual aids help align expectations across language barriers and time zones.

Compliance and certifications vary by product category and market. Consumer electronics need safety testing. Children’s products face strict material requirements. Research applicable standards early and design to meet them.

Pre-production samples bridge the gap between prototype and mass production. These units come from actual tooling but allow quality verification before full production runs. Test them thoroughly to catch any issues that only appear at scale.

Good product design separates market leaders from also-rans. The difference between a product people love and one they tolerate often comes down to thoughtful design decisions.

Strategic value starts with differentiation. When competitors offer similar features, superior design becomes your competitive advantage. Products that look better, feel better, and work better command premium prices and generate customer loyalty.

Usability directly affects consumer satisfaction. Intuitive products reduce frustration and support calls. Users recommend well-designed products to friends and family. This organic growth costs nothing but requires investing in the user experience from day one.

Market competitiveness improves when your product meets consumer needs better than alternatives. Design research reveals what matters most to your target audience. Delivering on those priorities positions your product as the obvious choice.

The numbers support design investment. Companies that prioritize design outperform industry benchmarks by 211% according to multiple studies. This return comes from faster time to market, lower development costs, and higher customer satisfaction scores.

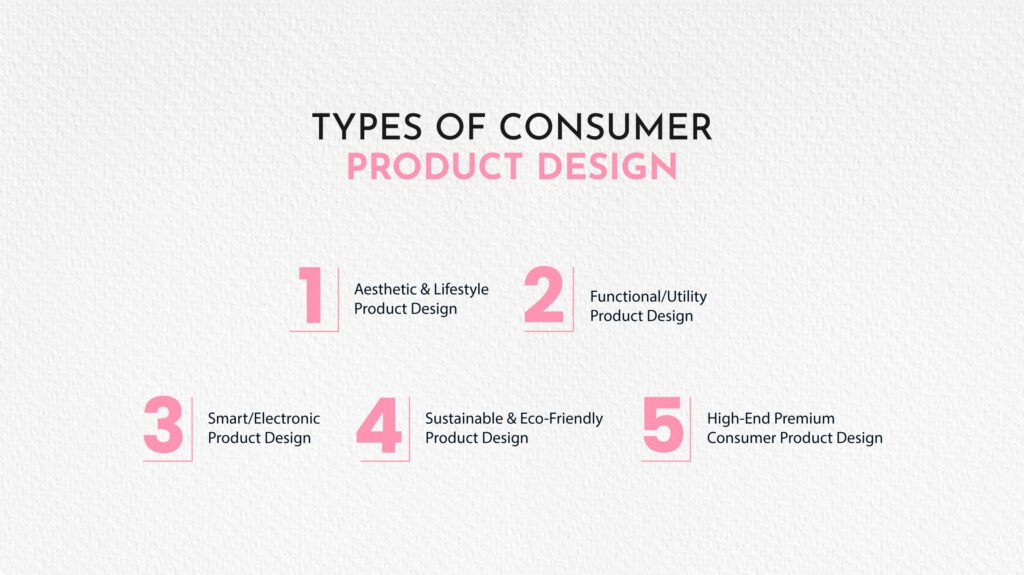

Consumer products span diverse categories, each with unique design considerations. Understanding these types helps you apply appropriate strategies to your specific product challenge.

These products prioritize visual appeal and emotional connection. Fashion accessories, home decor, and personal care items live in this category. Design choices focus on trends, self-expression, and lifestyle alignment.

Successful lifestyle products tap into aspirational identities. Color psychology plays an outsized role here. Certain colors trigger specific emotional responses that influence purchasing decisions. Understanding how much brand design costs helps budget appropriately for products where brand perception drives value.

Pure utility drives this category. Kitchen tools, cleaning supplies, and basic household items need to work reliably above all else. The best functional designs disappear during use because they require minimal thought.

Design efficiency focuses on task completion. Material durability becomes critical since these products face repeated use. Creating products that balance affordability with reliability requires careful engineering.

Consumer electronics blend hardware and software design. Smart home devices and wearables need intuitive interfaces plus reliable connectivity. Technical complexity must hide behind simple user experiences.

Electronics integration challenges designers to fit components into compact, attractive housings. Software user experience matters as much as physical design. Apps and interfaces should feel natural and responsive.

Environmental responsibility drives design decisions in this growing category. Recycled materials, minimal packaging, and repairable construction appeal to conscious consumers willing to pay premium prices for sustainable options.

Lifecycle thinking extends beyond initial purchase. Can components be separated for recycling? Do materials biodegrade safely? These questions shape every design choice.

Luxury products justify elevated prices through exceptional design, materials, and craftsmanship. Premium audio equipment and designer furniture compete on quality rather than cost.

Attention to detail separates premium from standard products. Hand-finished surfaces, precise tolerances, and thoughtful packaging all contribute to perceived value.

Real-world examples illustrate how good design solves actual problems. These case studies show how different product types apply design principles successfully.

OXO Good Grips Kitchen Tools revolutionized the household product category. Their founder struggled with arthritis and created ergonomic handles that anyone could grip comfortably. This universal design approach made their tools more appealing than cheaper alternatives.

Fitbit Activity Trackers succeeded in wearable tech by balancing functionality with style. Early fitness trackers looked too technical for everyday wear. Fitbit created sleek designs people wanted to wear constantly.

Ember Temperature Control Mug exemplifies premium kitchen gadget design. The product addresses a simple frustration with coffee cooling too quickly. App-connected heating maintains your preferred temperature for hours.

Product | Category | Key Design Innovation |

OXO Good Grips | Kitchen Tools | Ergonomic handles for all users |

Fitbit | Wearable Tech | Style plus function balance |

Ember Mug | Smart Kitchen | App-controlled temperature |

These examples share common traits. Each identified an underserved user need through research. Design teams created multiple prototypes and tested with real users. Success came from executing the complete process rather than skipping steps.

The right tools accelerate design work and improve quality. Modern product design software ranges from free options to professional suites.

CAD and 3D Modeling: Fusion 360 by Autodesk offers cloud-based CAD with both free and professional tiers. SolidWorks remains the industry standard for professional product engineering. Onshape delivers browser-based CAD that works on any device.

Rendering and Visualization: KeyShot creates photorealistic product renderings from CAD models. Figma works well for product concept presentation boards.

Prototyping Tools: Formlabs 3D printers bridge the gap between digital models and physical prototypes. Arduino and Raspberry Pi enable electronics prototyping for smart consumer products.

Choosing tools depends on project needs and budget. Start with free options while learning, then invest in professional tools as projects grow more complex. For teams looking to build digital product experiences alongside physical products, no-code development platforms can accelerate complementary web and mobile app creation.

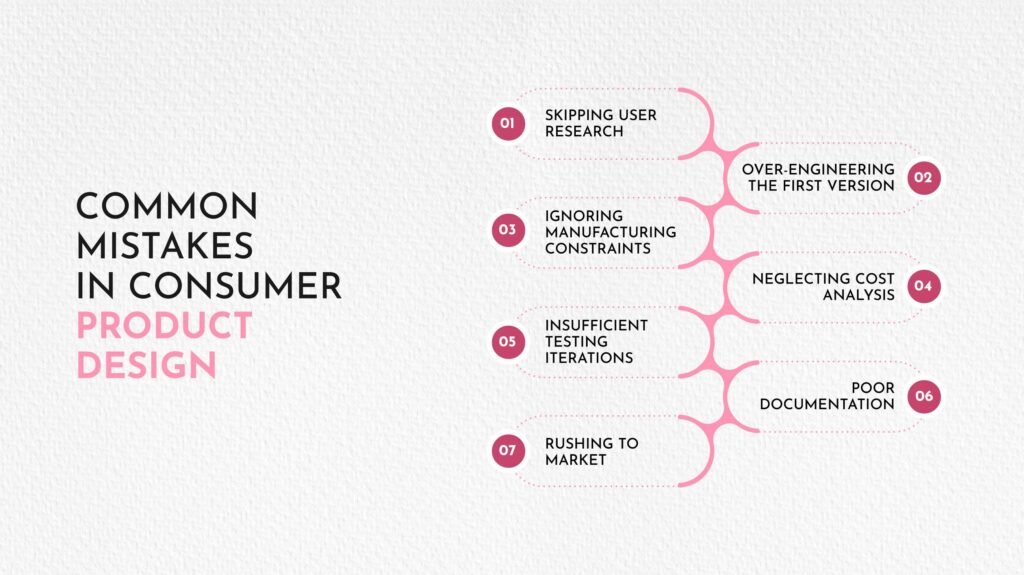

Even experienced teams make predictable errors. Learning from common mistakes saves time and money during your product development process.

Skipping User Research – Assuming you know what users want without asking them leads to products nobody needs.

Over-Engineering the First Version – Trying to include every possible feature creates complexity that delays launch.

Ignoring Manufacturing Constraints – Designing without consulting manufacturers results in expensive redesigns.

Neglecting Cost Analysis – Beautiful designs that cost too much to produce never reach market.

Insufficient Testing Iterations – Shipping the first prototype rarely works. Budget time for multiple rounds of testing.

Poor Documentation – Inadequate technical drawings cause production errors.

Rushing to Market – Launching before products meet quality standards damages brand reputation.

Avoiding these pitfalls requires discipline and patience. The consumer product design company that succeeds is the one that respects the process rather than cutting corners.

Consumer product design transforms ideas into physical products people love using. The journey from concept to manufacturing requires research, creativity, engineering, and validation.

Success comes from staying focused on user needs throughout the process. Products that solve real problems in elegant ways generate customer loyalty and strong sales. The investment in proper design process pays dividends through reduced returns and positive reviews.

Ready to bring your product idea to life? Start by defining the problem you want to solve. Then work through each stage systematically rather than rushing to market. Many successful product companies complement their physical offerings with strong digital presences – working with a website design company for small business can help establish your brand online as you prepare for launch. The best consumer products come from teams that respect the design process.

What is consumer product design?

Consumer product design is the process of creating physical products for everyday use by researching user needs, developing concepts, engineering solutions, and preparing designs for manufacturing. It combines industrial design, engineering, and user experience to create products that meet consumer needs.

How long does it take to design a product?

Product design timelines vary widely based on complexity. Simple products might take 3-6 months from concept to manufacturing. Complex consumer electronics often require 12-18 months. The process includes research, concept development, prototyping, testing, and manufacturing preparation.

What is the difference between industrial design and consumer product design?

Industrial design is a discipline focused on form, function, and manufacturing of physical products. Consumer product design is a broader process that includes industrial design plus market research, engineering, testing, and business strategy. Industrial design is one component of complete consumer product development.

How much does consumer product design cost?

Costs range dramatically based on product complexity and team expertise. Simple products might cost $10,000 – $50,000 for design and prototyping. Complex electronics can easily exceed $100,000-$500,000. Working with consumer product design firms provides cost estimates based on your specific requirements.

Do all products need prototyping?

Yes, prototyping is essential for nearly all physical products. Prototypes let you test functionality, gather user feedback, and validate manufacturing approaches before expensive tooling. Even simple products benefit from physical prototypes that reveal issues impossible to catch in CAD models alone.

Angela Schmidli is the Founder and CEO of Webwonder. She helps entrepreneurs and businesses build strong online identities through web design, branding, SEO, and strategic marketing.